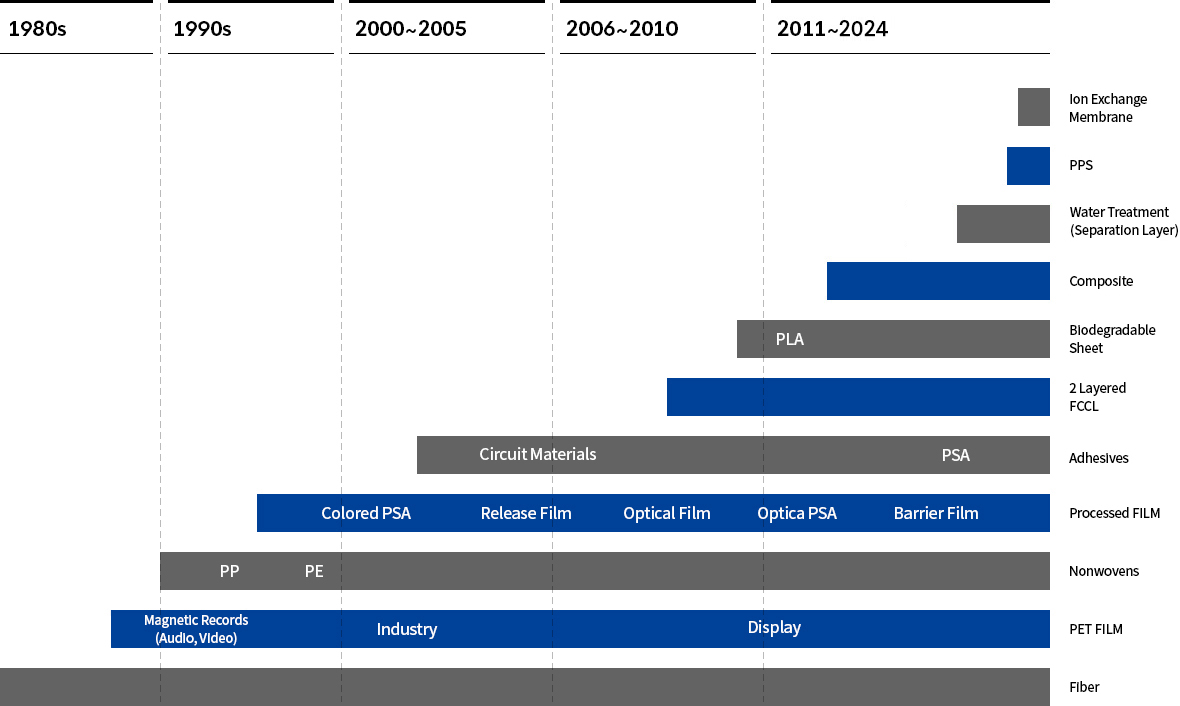

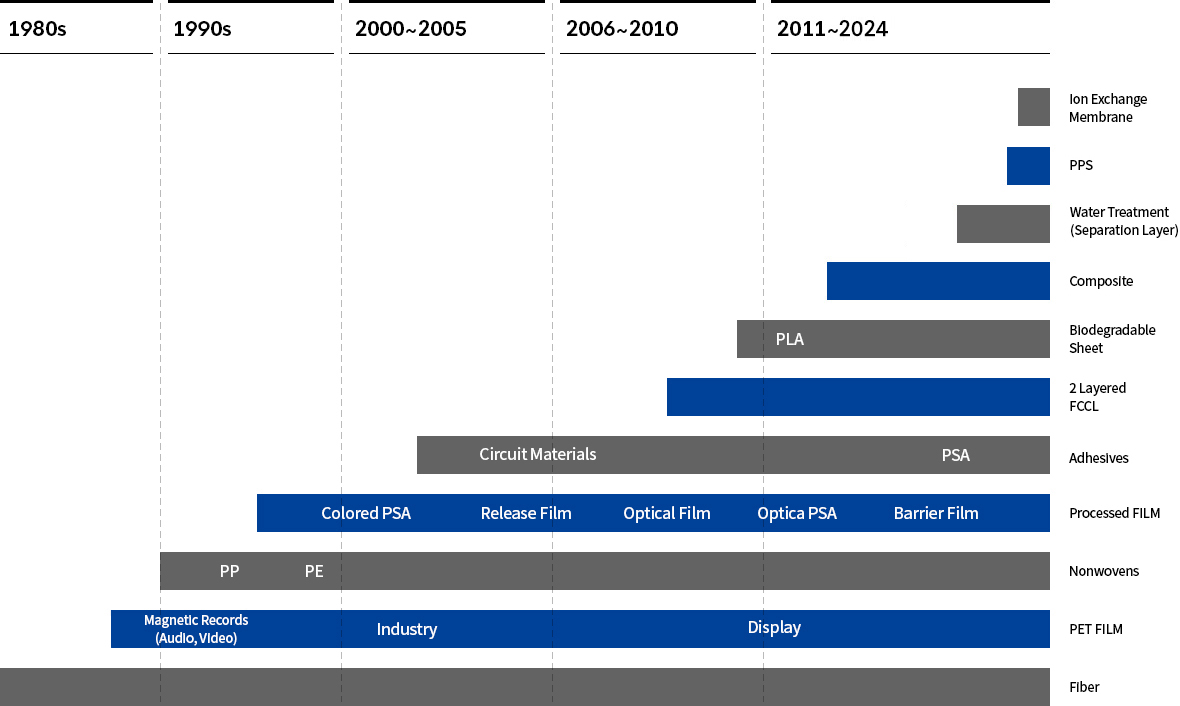

Status of R&D Expansion

Greatly contributing to improving the quality of human life through

advanced technology and innovative product

We, Toray Advanced Materials Korea Inc. have contributed to improving the quality of human life through development of high tech materials. Furthermore we will continue to fulfill our role as an innovation partner creating a better future with the highest quality materials developed through technological convergence.

ㆍOrganic Color Conversion Sheet for control harmful

blue light

ㆍBase film for Smart Window

ㆍRelease film for polarizer

ㆍPET protective film for foldable

ㆍFluorine-based and MPI-based 2-layer

FCCL for high-speed transmission

ㆍOrganic Color Conversion Sheet

(Green Color Sheet)

ㆍHigh Barrier Metalized Film

ㆍQDEF Thin Barrier Film

ㆍFormable protection film for 3D forming

ㆍFluorine release film for mobile devices

ㆍILC antistatic lightly peelable release film

ㆍOLED support base film

ㆍBase film for white multi-layer release film

ㆍIn Line coated Release Film for MLCC

(General Purpose)

ㆍLamination prism film

ㆍBarrier Film for QDEF

ㆍRelease Film for OLED Encap

ㆍRelease Film for ILC Polarizer Protection

ㆍOLC MLCC Super-flat Release Film

ㆍReflective Film for Direct TV

ㆍMLCC-Embedded PCB Processing Tape

ㆍNPG Contraction Film

ㆍAnti-oxidation Film for TSP

ㆍQFN Package-AP Adhesive

ㆍEVA Sheet for solar cells

ㆍBase Film for Hard Coating

ㆍBack Sheet for solar Cells

ㆍBase Film for BLU Reflection

ㆍMobile Hard Coating Film

ㆍNon-halogen Coverlay Film

ㆍILC prism base film

ㆍRelease film for ILC MLCC

ㆍOff Line Coated Anti-reflective Film for PDP

ㆍRelease film for OLC polarizer (plate)

ㆍBase film for LCD light diffusion

ㆍOLC vertical diffusion film

ㆍOLC Lead Frame Fixing Tape

ㆍILC Silicone Coated Base Film

ㆍRelease film for OLC MLCC

ㆍILC PU Coated Film

ㆍPET Film whit Raough Matte

ㆍOLC LLT (Lead Lock Tape)

ㆍCut sheet

ㆍDevelopment of bipolar membrane for electrodialysis

ㆍDevelopment of high pressure durable NF products

ㆍDevelopment of high-performance eco-friendly

reverse osmosis separation membrane for home use

ㆍDevelopment of dry-type industrial reverse osmosis

modules

ㆍHigh-concentration ion exchange membrane

developed

ㆍIon exchange membrane for lithium

production/recovery developed

ㆍHigh durability Low pressure RO Membrane developed

ㆍDirect purified RO module for home use developed

ㆍSulfonated nano separator developed

ㆍNano-membrane for removing sulfate

ㆍNano membrane for hardness removal developed

ㆍUltra high volume RO membrane for home use developed

ㆍRO membrane using wastewater developed

ㆍAcid resistant nano membrane developed

ㆍUltra high volume antifouling RO

membrane developed

ㆍAntifouling RO membrane having high salt rejection

property for home use developed

ㆍPRO (Pressure Retarded Osmosis) membrane developed

ㆍPositively charged filter (OLBIO-CUT) developed

ㆍDeoxidized water nano membrane for home use developed

ㆍLow pressure antifouling RO membrane developed

ㆍFO (Forward Osmosis) membrane developed

ㆍUltra filtration for electrodeposition coating and food processing

ㆍSulfate-free nano membrane developed

ㆍDry RO membrane for home use developed

ㆍMonovalent / divalent separation nano membrane developed

ㆍAntifouling RO membrane having high salt rejection property developed

ㆍAntifouling RO membrane for sea water desalination developed

ㆍChlorine-resistant RO membrane

ㆍHigh-performance nano-membrane

ㆍRO membrane for ultra pure water for semiconductors

ㆍAntifouling RO membrane developed

ㆍRO membrane with high salt rejection for desalination of seawater

ㆍLow-pressure RO membrane for industrial use

ㆍDevelopment of contact cooling functional fibers(SNOLENE)

ㆍDevelopment of high-sound-absorbing hybrid

meltblown nonwoven fabric(Airlite AM)

ㆍDevelopment of antimony-free short cut,

an eco-friendly R/O nonwoven material

ㆍChemical recycling polyester fiber,

Ecoway developed

ㆍDope dyed Meta-aramid developed

ㆍ100% recycle latent crimped yarn developed

ㆍHeavy Metal Free-LM for sanitary goods developed

ㆍMeta aramid filament developed

ㆍBiodegradable polyester fiber developed

(Ecoway™-B)

ㆍHybrid meltblown acoustic absorbent for

automotive (Airlite)

ㆍLow melting fiber for elastic nonwoven fabric

developed (E-plex™)

ㆍDevelopment of meta aramid staple fiber

completed (Arawin™)

ㆍRecycled polyester fiber (Ecoway™-C) developed

ㆍPolyester fiber developed using non-heavy-metal catalyst

ㆍMemory form material

ㆍLow-temperature melting filament, anti-bacterial staple fiber

ㆍFilament and staple fiber for synthetic leather, low-temperature melting fiber

ㆍQuick absorbing and drying filament

ㆍDown-like staple fiber

ㆍFlame-retardant staple fiber

ㆍDevelopment of high-permeability filter media

for type 5 and 6 protective clothing

ㆍDevelopment of PET nonwoven secondary base

fabric for automobiles

ㆍDevelopment of low weight/high strength

nonwoven fabric

ㆍEco-friendly PLA SB nonwovens developed

ㆍAntibacterial SB nonwovens developed

ㆍElectrostatic SMS Spunbond nonwoven for masks developed

ㆍHigh light-stability PP nonwoven developed

ㆍHigh-loft nonwoven fabric developed

ㆍMaster batch type hydrophilic SB

ㆍFunctional hygiene Topsheet SB

ㆍPET SB for PVD

ㆍSoft SMMS SB

ㆍPET SB for automotive battery base film

ㆍPET SB for housewrap

ㆍEco-friendly nonwovens

ㆍHollow PET SB nonwovens

ㆍPE/PP Bi-component SB

ㆍSSMMS, Multi-layer SB

ㆍSSS, SMMS, Multi-layer SB